If you’re found to be in material breach of Health and Safety law, you will have to pay for the time it takes the inspector to identify the breach and subsequently advise what you need to do to put things right. This includes investigating the issues themselves and taking any enforcement actions.

There are several key areas we’ve discovered are becoming more popular for the HSE to focus on. So, in addition to making sure your risk assessments are in place and up to date, here are some of the most common ones, and the most important checks you can make to make sure that you’re covered should an inspector turn up at your door.

CoSHH and occupational hygiene

Have appropriate COSHH assessments been completed for substances in use in your business?

If you’re welding, do you know the makeup of the fume and required control measures?

If welding is undertaken, can the fume be controlled at source via the use of on-tool extraction? Is Local Exhaust Ventilation a suitable alternative?

If you use metalworking fluids, have you assessed the risks to workers of long term exposure and inhalation? Do you have bacterial testing measures in place with records kept?

Has appropriate training, instruction and supervision been given to employees about hazardous substances within the workplace (consider cutting fluid, wood dust and welding fume) themselves? Have you communicated the risk / CoSHH assessment findings?

Has air/exposure monitoring been undertaken and recorded to ascertain suitable controls are in place?

Is Respiratory Protective Equipment required, if so what type?

Is a minimum assigned protection factor required?

Has face-fit testing been completed? (using a Fit2Fit accredited tester)

Has a DSEAR assessment been undertaken if required?

Can the dangerous substances identified be substituted for a less hazardous alternative, the quantity reduced, or the work process changed to reduce the risk?

Are measures in place to reduce employees exposed to effects of dangerous substance?

Do drivers have required training and licensing to drive the vehicle?

Is an appropriate evacuation and emergency procedure in place?

Noise and vibration

Have noise risk assessments been undertaken for the workplace and hearing protection zones / control measures implemented?

Have Hand Arm Vibration (HAV) and Whole Body Vibration (WBV) assessments been undertaken for the workplace and control measures implemented?

Is health surveillance in place where required for: Hazardous Substances, Noise and Vibration?

Machine maintenance and guarding

Has the task been risk assessed and a safe system of work developed?

Are all respective guards or interlocks in place? Have you inspected these prior to use?

Has the operational manual been reviewed to consider requirements for maintenance?

Have the operators and engineers been appropriately trained in process and maintenance requirements?

Is there a lock-out, tag-out procedure in place?

Prior to starting the work has the machinery been purged of any stored energy or hazardous substances?

Workplace transport

Has an appropriate risk assessment been completed that considers transport?

Has this considered blind spots? Bends? Pedestrian interactions? Gradients?

Is the site large enough for activities required? Loading/unloading, reversing etc.

Are vehicle routes wide enough for the types of vehicle needed?

Do drivers have required training and licensing to drive the vehicle?

Has a one way or traffic management system been implemented? What are the pedestrian segregation controls?

Working at height

Is a suitable and sufficient Risk Assessment in place?

Has it been completed by a competent person with involvement of the employees undertaking the work?

Has it been communicated to relevant parties? (i.e. those completing the work and those who may be affected by hazards arising from the work.)

Is the work at height planned, organised and carried out by competent persons?

Are ladders being used? Are they the correct type? Have they been inspected before the task is carried out?

Has adverse weather been considered if working outside?

Is access equipment being used? If so, what is the maintenance schedule? Is it the right equipment? Has it had its LOLER examination?

Is a work-restraint system in place? Is it suitable to prevent employees from accessing the edge/an area where they could fall?

Contact us if you require further information.

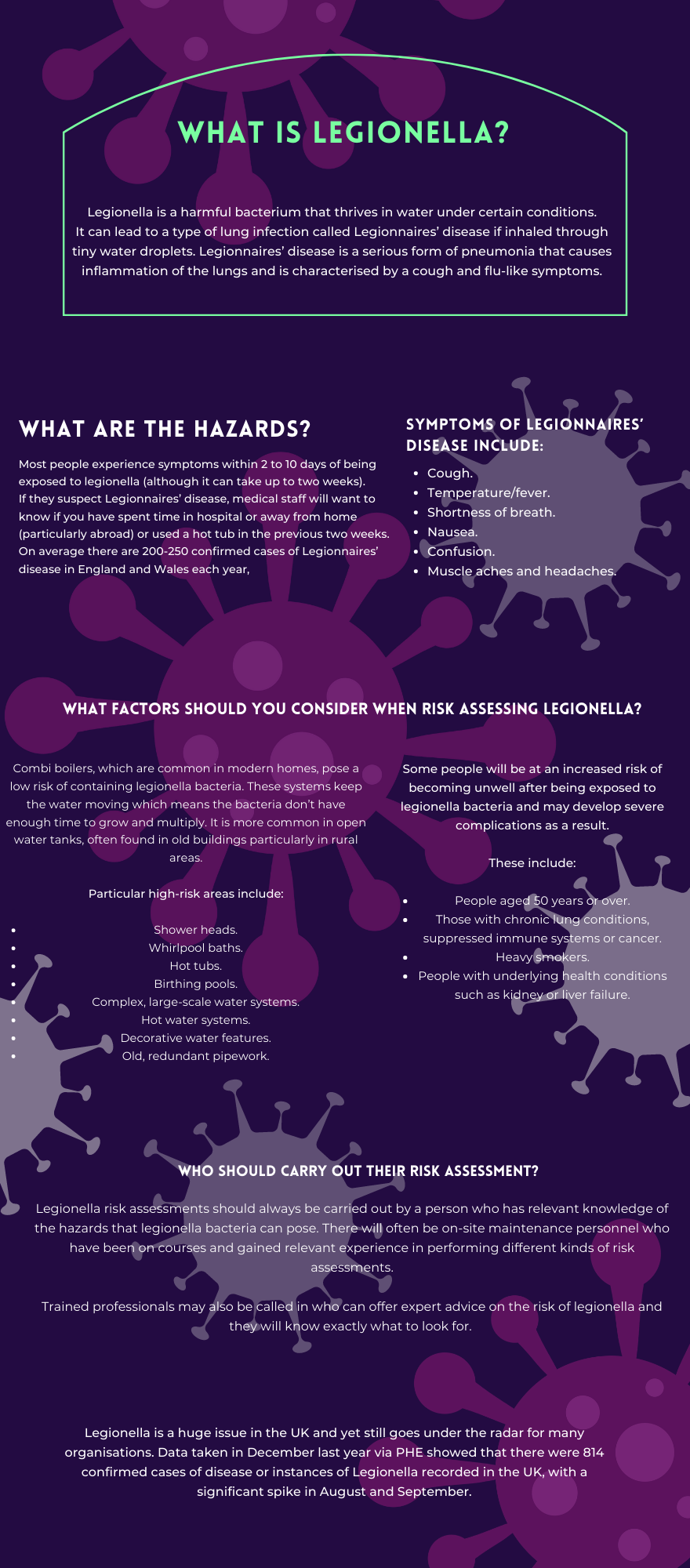

A legionella assessment is an essential risk management process. It comprises a detailed examination of the risks presented by man-made water systems, and seeks to identify and assess the risks associated with Legionnaires’ disease through exposure to the bacteria.

We have put together an infographic. I would recommend that you share the information with employees as it could be beneficial to them.

Contact us for further information.

Importance of Updated Safety in the Workplace

Safety in the workplace is essential. Part of safety protocol entails inspecting and replacing any damaged equipment. Personal protective equipment (PPE) applies to any industry. It’s helpful to know what PPE your team should wear as well as the stationary equipment available to keep everyone safe.

Why Is it Important to Inspect for Damage and Replace Equipment?

There are several factors to consider when inspecting damaged equipment and replacing it. Dangerous and risky job sites require that personal protective equipment, like helmets, must always be worn to avoid fatal accidents such as falling objects. All PPE must be working correctly and replaced regularly.

Inspect and Replace PPE in a Timely Manner.

Identify the correct time to replace PPE. Replacing equipment too early is a waste of resources to pay for new equipment. However, waiting too long to replace PPE is risky because, if equipment fails, accidents and injuries happen.

Develop Standards and Protocols for Inspecting PPE.

Establish inspection timelines, standards and protocols. For example, everyone could be responsible for their personal protective equipment, or one or two people could be assigned responsibility for inspecting the equipment. If and when there is an issue with the equipment, it should immediately be taken out of circulation and replaced. Therefore, you should always have extra PPE on hand.

When creating inspection protocols, you need to be aware of what to look for when inspecting PPE. Some examples of what to inspect include:

Use a PPE Grading System.

Create a PPE grading system. A grading system should be common to everyone and helps your employees instantly know when equipment should be replaced. PPE may need to be replaced while it’s getting fixed or may need to be thrown out altogether. It all depends on the type of job.

Use Occupational Safety and Health Administration Guidelines.

Refer to The Health and Safety Executive (HSE) and Government guidelines. Be sure that your team knows exactly what the guidelines are and be sure they are met at all times. These guidelines can be included in your inspection and replacement requirements.

COVID and PPE

When managing the risk of COVID-19, additional PPE beyond what you usually wear may not be beneficial. This is because COVID-19 is a different type of risk to the risks you normally face in a workplace, and needs to be managed through social distancing, hygiene and fixed teams or partnering, not through the use of PPE.

The UK Government has published COVID-19 Secure working safely guidance for workplaces that provides a hierarchy of risk control measures that employers and the self-employed are expected to follow when reviewing their risk assessments for COVID-19 hazards.

When an Incident Occurs, Take Action Immediately.

Take action after an incident. Any affected PPE should always be replaced. Depending on the incident, it may be possible to save the gear after being inspected. Otherwise, it should be replaced.

Don’t Forget About Stationary Equipment

Be aware of stationary equipment like machinery and the need to stand behind a protective shield. This equipment also requires you to inspect, repair, and/or replace the stationary equipment as well.

Be Consistent.

Though replacing and inspecting equipment may seem like a hassle, it is better to be safe than sorry. Make sure your workers are aware of necessary PPE and inspect their gear at the beginning of a shift or before starting a major project. You do not want to risk an accident.

What PPE Wear Is Available?

PPE wear includes head protection, eye protection, hearing protection, good respiratory protection, correct gloves, footwear, and correct work clothing.

Here are examples of the different types of PPE wear available.

Head Protection

Invest in a good helmet. Today, there are many customised features to choose from such as adjustable interior harnesses and sweatbands. Ensure PPE is compatible, for example, wearing a safety hat in conjunction with ear defenders.

Eye Protection

Work-related eye injuries unfortunately happen to hundreds of people daily worldwide. Safety glasses can prevent these injuries. Welding goggles and shields can protect you from bright light or infrared radiation.

Hearing Protection

In a high sound level environment, earplugs would be comfortable. However, ear defenders may be a better choice to have on the shop floor or construction site because you can take them on and off easily and they’re more hygienic.

Respiratory Protection

Masks are necessary when coming in contact with hazardous materials like vapour, smoke, or powder. Dust masks protect you against fine dust and other dangerous particles. Full-face masks protect you against toxic materials. These masks will protect your nose and mouth from pollution.

Hand Protection

There are different types of gloves depending on your occupation.

Protective Footwear

Different types of protective footwear serve different purposes

Correct Work Clothing

Specific types of work clothing can protect against accidents in a crowded workshop. High-visibility vests or jackets can keep you visible in dark or crowded conditions. Pants made with strong fabric will protect your skin and resist wear and tear.

Ensure the team are trained and competent to carry out their tasks.

Safety in every workplace is a must to provide a safe work environment, and keep you and your team safe.

Contact us for further information.

Why have this talk? Statistics show that alcohol and drug misuse are increasing in the workplace. This talk is to make all employees aware of their responsibilities and understand that alcohol and drug abuse in the workplace can lead to accidents.

What will this talk cover? The effects of alcohol and drugs on your safety and that of others.

Toolbox Talk: Alcohol and Drugs at Work

Alcohol is a depressant drug which reduces brain function. This means it does not mix well with work. In high risk industries, alcohol increases the risk of fatal accidents.

If you drink, don’t drive. Many drivers who are killed in road accidents are over the legal alcohol in blood limit.

All drugs can affect your ability to work safely because they can slow down your reaction times, affect your co-ordination making you clumsy, affect your decision making and distort your vision. As a result, the chance of having an accident at work is increased when you are under the influence of drugs.

If you become aware that somebody is on drugs in the workplace, inform your line manager. You may feel it has nothing to do with you but you need to prevent others getting hurt because of their actions.

If you get offered drugs, say no, it is far better to work safely. Drugs and work don’t mix. Don’t let it become a problem for you and if is, get some help.

Some signs of colleagues being under the influence of drugs include watery eyes, dilated pupils, running nose, constant sniffing, tight lips, sores, ulcers, trembling, fatigue and irritability. If you see it, report it.

Contact us if you have any questions.

Accidents can happen on any day. The day they are most likely to happen is the day health and safety have been forgotten. Health and safety can’t have days off!

By starting each day with a quick 5-10 minute toolbox talk, it serves as a reminder about the importance of health and safety at work. It gets peoples minds focused on the hazards and risks they are about to face. It reminds them of what they need to do to stay safe. It starts the day with a positive health and safety attitude.

Informal toolbox talks can often be missed or carried out too infrequently. The benefit of a daily toolbox is that it becomes part of a routine. Part of the working day.

Carried out daily, toolbox talks become part of a habit. A habit that will help the team develop a positive health and safety attitude. A habit that creates a safer work environment.

What business doesn’t want a positive health and safety culture? It keeps your workers safe, keeps your business out of trouble, and can save you money. That’s a triple win! So why do some businesses have poor health and safety records? Because growing a positive health and safety culture takes time and effort, and everyone’s involvement.

Your health and safety culture is the values, attitudes, competency and behaviours of everyone in the business. Regular toolbox talks can form part of the health and safety management system to grow your health and safety culture in a positive way.

In some instances, dangers arising from hazardous activities can only be controlled using personal protective equipment, known as PPE.

The importance of PPE and how to use it correctly to ensure effective protection.

Personal Protective Equipment Toolbox Talk

The legislation requires any employer who identifies it as necessary to supply PPE and ensure that it is used at work wherever the risk to health and safety cannot be controlled in other ways.

PPE is equipment or clothing designed to protect the user from known hazards in the workplace. The most commonly worn items of PPE are safety footwear, gloves, safety glasses or goggles and hi-vis clothing. You might also use helmets, ear protection (for noise), respirators and safety harnesses.

PPE is designed to only protect the user.

All PPE must be worn in accordance with the manufacturer’s instructions and be in good condition to be fully effective.

Anyone using PPE needs to be aware of why it is needed, when it is to be used, repaired, or replaced. They should also be aware of the limitations of the PPE they use, for example safety gloves can come with different cut levels. A different cut level may be required depending on the risk involved of the task.

Contact us if you have any questions.