ISO 45001 is the global standard for managing health and safety in the workplace. It helps organisations of all sizes create safer, healthier environments by identifying risks, reducing hazards, and involving everyone — from leadership to frontline workers.

This isn’t just about ticking boxes. It’s about protecting people, improving wellbeing, and building a positive safety culture that benefits your business and your team.

Whether you’re a small business or a large company, ISO 45001 is a practical tool that shows your commitment to doing things right — and keeping people safe.

Contact us for further information.

Due to their lack of maturity, experience and hazard awareness, young people may perceive risk differently to more practiced employees. There is also a raft of various regulatory instruments in place to limit young people’s exposure to specific physical, chemical and biological risks as they are at increased danger of harm from these. This article looks at the factors employers need to consider to instil safe behaviour among a young workforce.

Due to their lack of maturity, experience and hazard awareness, young people may perceive risk differently to more practiced employees. There is also a raft of various regulatory instruments in place to limit young people’s exposure to specific physical, chemical and biological risks as they are at increased danger of harm from these. This article looks at the factors employers need to consider to instil safe behaviour among a young workforce.

A young person is defined in legislation as any person under the age of 18 who is not a child, i.e. someone who has not yet reached the minimum school leaving age of 16.

In terms of the health and safety of young workers, there are two primary considerations for employers when it comes to reviewing their risk assessment.

Lack of training and experience

Before a young person starts work, the employer’s risk assessment must take into account a young person’s lack of experience, training and awareness of risk as well as their immaturity.

Risk assessments need not be overly burdensome or bureaucratic, eg in an office or shop environment, the organisation’s generic risk assessment is likely to be sufficient and the control measures in place are likely to be familiar to young persons. However, in higher-risk environments, consideration needs to be given to how young people may be influenced or pressured into unsafe work practices by older colleagues or peers, how they may be curious and act unpredictably despite any instructions or training they may have been given to the contrary or how they may also deliberately violate rules and procedures, eg in feeling pressure to get a task done, they take shortcuts.

Appropriate control measures in these cases include:

Specific risks

In higher-risk environments, such as in assembly, industrial or construction sites, along with considerations of a young person’s lack of maturity and experience, specific risk factors also need to be reviewed and additional arrangements are likely to be required.

Exposure to physical hazards

Young persons have a physical immaturity and an increased risk of musculoskeletal damage as bones and supporting muscles are not fully developed until a person is approximately age 25. This means high levels or prolonged periods of exposure to vibration — particularly low-frequency whole-body vibration — should be avoided.

Young people may be less skilled in handling and moving techniques or in pacing their work tasks to match their capacity. Other jobs that require repetitive or forceful movements, particularly when in association with awkward posture and/or insufficient recovery time, should be given careful consideration. Manual handling of tools and equipment to assist with difficult handling tasks, introduction of task rotation and provision of sufficient rest breaks may be necessary.

Young people should not be permitted to use high-risk lifting machinery such as cranes, lifting accessories and construction site hoists, unless they have had the appropriate level of competence and training. As part of their training, they may use such equipment, providing they are adequately supervised. Adequate supervision should also be provided after training if a young person is considered not sufficiently mature.

The duty to carry out periodic, thorough examinations or inspections of lifting equipment or the planning and supervision of lifting operations, should not be placed on a young person but discharged by a competent adult employee.

Young persons should also not be permitted to use high-risk work equipment (such as abrasive wheels, circular saws, power presses and band saws), apart from during training which is adequately supervised.

The dose limit of ionising radiation should be set at a lower level than that for other employees — doses must not exceed 6mSv in any calendar year.

Exposure to chemical hazards

Many chemical agents can have adverse health effects on young people, although they are typically not considered to be at any greater risk than other employees and control measures currently in place to prevent employee exposure are likely to be sufficient for young people also. Safety data sheets will provide full details on specific agents.

However, a lack of perception of danger may prevent young people from recognising “invisible” or long-term health effects that may take many years to develop. For this reason, specific prohibitions are in place around agents such as lead and asbestos.

Young persons may not be involved with specific lead smelting and refining processes or in lead battery manufacturing process. Exposure to lead alkyls is particularly hazardous and its absorption into the body can produce a rapid toxic effect. Employers should ensure that adequate and proper safeguards are in force to protect the health of any young person employed on storage-tank cleaning work, which could potentially expose them to lead alkyls.

Younger people, if routinely exposed to asbestos fibres over time, are at greater risk of developing asbestos-related disease than older workers. This is due to the time it takes for the body to develop symptoms after exposure to asbestos. Similar concerns exist for exposure to silica dust in the construction industry leading to silicosis and other related lung diseases. Employers need to give information about the impact of these risks and the serious potential consequences of exposure to young people in their employment.

Exposure to biological hazards

The Advisory Committee on Dangerous Pathogens recommends that young people do not handle animals infected with biological agents assigned to hazard group 4, ie those that cause severe human disease, pose a serious risk to employees, are likely to spread to the community and that have no effective prophylaxis or treatment available.

Duties of young persons

In turn, employers should inform young persons of their legal responsibilities towards the employer. This means following any safety arrangements implemented for their protection, including attending training sessions and complying with control measures, not acting in a manner that adversely affects their own health and safety and/or the health and safety of anyone else and to report any perceived or real shortcomings in protection levels to their employer.

In conclusion, a key component in managing the health and safety of young persons is the ongoing communication of safety messages and the guidance of mentors/supervisors to reinforce the true level of risk among young people and improving their perceptions of risk through training.

Contact us for further information.

As the UK heads into summer, longer days and (hopefully!) warmer weather bring a seasonal boost—but also fresh health and safety challenges for both indoor and outdoor workers.

As the UK heads into summer, longer days and (hopefully!) warmer weather bring a seasonal boost—but also fresh health and safety challenges for both indoor and outdoor workers.

Whether you’re managing a construction site, waste operations, grounds maintenance or logistics, it’s essential to adjust your approach as the environment changes. Here are some timely reminders and practical tips to help keep your workforce safe and productive through the warmer months.

🌡️ Heat Stress Is a Real Risk

Even in Britain, when temperatures rise suddenly, our bodies—and working practices—need time to adjust.

Watch out for signs of heat stress:

What can employers do?

👷 PPE in the Heat

Workers still need PPE—no matter the weather—but some kit can make hot conditions worse.

Tips:

🧴 Sun Protection

Sunburn isn’t just uncomfortable—it increases long-term skin cancer risk.

Encourage outdoor staff to:

Remember: UV exposure can still be high on cloudy days.

🚜 Vehicle & Machinery Checks

Warm weather can increase strain on vehicles, especially those used in waste, construction, and logistics. Watch for:

Top tip: Remind operators to do visual and hands-on checks at the start of each shift.

🧠 Stay Mentally Sharp

Heat can impact concentration. That increases the risk of mistakes, near misses, or accidents—especially in safety-critical roles.

What helps:

In Summary

Summer brings its own safety risks—but they’re all manageable with forward planning, open communication, and proactive support.

Review your risk assessments, update your toolbox talks, and check that your team knows how to spot early signs of heat-related illness. Most importantly, remind them that their health comes first—no task is worth risking long-term harm.

Stay safe, stay hydrated, and enjoy the sunshine (responsibly)!

Here is a toolbox talk to provide to staff. Click Toolbox_Talk_Summer_Safety

Contact us for further information.

As workloads shift with the seasons, so do the risks we face. Now is a perfect time to reinforce safe manual handling practices and prevent musculoskeletal injuries across your team.

As workloads shift with the seasons, so do the risks we face. Now is a perfect time to reinforce safe manual handling practices and prevent musculoskeletal injuries across your team.

Whether you’re lifting, shifting, pushing, pulling, or simply standing for long hours—strains and sprains are the most common workplace injury in the UK. The good news? They’re also among the most preventable.

🤕 The Cost of “Just a Twinge”

We’ve all heard it: “It’s just a sore back—I’ll shake it off.” But injuries like:

Many of these injuries result from poor lifting techniques, rushing tasks, or using the wrong equipment.

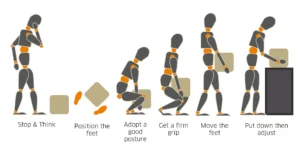

🛠️ 5 Manual Handling Tips to Share with Your Team

📋 Don’t Forget: Employer & Employee Responsibilities

Under the Manual Handling Operations Regulations 1992, employers must:

Employees must:

✅ What Can You Do This Week?

👀 Remember: Good habits save backs, joints and time.

Small changes in how we lift, carry, and move can make a huge difference in injury prevention. Let’s keep sprains and strains off the sick list this summer.

Here is a toolbox talk to provide to staff – Click here Toolbox_Talk_Manual_Handling.

Contact us for further information.

Contact us if you wish to discuss your health and safety requirements 🙂

Health and Safety Consultants | Telford, Shropshire, West Midlands