Driving Responsibly

Employees must adapt their driving to winter hazards:

These behaviours align with health and safety law, which applies to work-related driving just as it does on-site.

Legal and Employer Expectations

Under UK law and employer policies, employees must:

Employers are required to manage road safety risks, but employees play a key role in executing those plans.

Emergency Preparedness

Employees should carry a winter emergency kit, especially for longer journeys:

This is particularly important for lone workers or those driving in rural areas.

When Not to Drive

If conditions are too dangerous, employees should:

Employers must support safe decision-making and not penalize employees for refusing to drive in hazardous conditions

From 4 September 2023, HSE inspectors will be carrying out inspections of construction sites, focusing on the health risks of moving and handling materials on site.

From 4 September 2023, HSE inspectors will be carrying out inspections of construction sites, focusing on the health risks of moving and handling materials on site.

Around 42,000 construction workers suffer musculoskeletal disorder (MSDs) which can cause years of agonising aches and pains.

Serious aches, pains and strains can affect every part of someone’s life.

Construction site inspections focused on moving and handling in materials throughout September and October.

If you don’t know where to start and what is needed, we can do a full health and safety audit on your premises.

Contact us for further information.

Asbestos Toolbox Talk

Why have this talk? Asbestos Toolbox Talk. Asbestos is a naturally occurring mineral and because of its excellent fire retarding and insulating properties it was widely used in the building industry in the 1980s.

Research has shown that breathing in asbestos fibres may cause lung disease and cancer and it is currently the greatest single cause of work-related deaths in the UK with several thousand people dying each year. The delay between asbestos exposure and disease can range between 10 and 50 years.

What will this talk cover? Where you might find asbestos and how to work around it.

| The use of asbestos is now banned but any building that was built before 2000 could have asbestos in it. As long as the material is not disturbed, workers should not be alarmed. If existing asbestos materials are in good condition, they can be left where they are as long as their condition is regularly checked to ensure they do not become damaged. Products where the asbestos is bound tightly (eg asbestos cement sheets or flooring tiles) are less hazardous than products such as pipe lagging which easily give off fibres, but all products need careful handling by trained workers. |

| The only way to reliably check if asbestos is present is to have a sample of the material examined in a laboratory. All potential asbestos-containing materials must be treated with caution. |

Do you have any questions for me?

Contact us for further information.

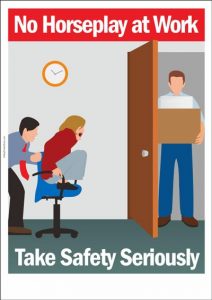

No Horseplay at Work

Rough, boisterous play or pranks in the workplace can have serious consequences. We look at key cases involving practical jokes at work and offer tips on how to prevent horseplay.

What is horse play?

Playing around, racing, grabbing, thoughtless vehicle operation, social pressure, harassment, and unauthorised contests are activities often encouraged by ‘practical jokers’ who pressure other colleagues to get involved. Playing jokes and having fun with colleagues can break up the day, provide stress-relief and make work more interesting, however horseplay can take this too far and put workers at risk.

Cases involving horseplay are common in industrial workplaces such as construction sites, and often where forklift trucks are used. But other cases have included pharmacies, hospitals and offices where pranks such as pulling out a chair has resulted in injury. Regardless of the sector, it is management’s responsibility to ensure all employees have access to a safe, respectful and harassment-free place to work.

The Health and Safety at Work Act 1974 does not specifically discuss horseplay but does make requirements for employees regarding health and safety.

Section 7 of the Act requires employees to ‘take reasonable care for the health and safety of himself and of other persons who may be affected by his acts or omissions at work’.

Section 8 requires that no person shall intentionally interfere or misuse anything provided in the interests of health, safety, and welfare. These duties extend to avoiding silly or reckless behaviour, and those who fail to comply with these duties may make themselves liable to be prosecuted.

However, acts that are not directly related to work, and are more of a personal nature will not be within scope, such as an employee assaulting a supervisor because he believed the supervisor had stolen his wallet.

It is most likely that employees will be prosecuted under section 7 where they have shown a reckless disregard for health and safety, and such disregard has resulted in serious risk.

Who is responsible?

It is a common misconception among employees that health and safety is the sole responsibility of the employer and if an accident or incident were to occur due to horseplay, that resulted in the injury of another person, it would be the employer that would have full responsibility. However, pranks at work that injure or threaten to injure another person may be the subject for individual prosecution against the person responsible. The law of vicarious liability has been steadily expanding, but there are areas where responsibility is still unlikely to arise on the part of the employer.

Last month IOSH magazine reported on Chell v Tarmac [2020] EWHC 2613, the latest decision to demonstrate that it will be difficult for an employee to succeed where they have been the victim of a practical joke played on them by a colleague.

Employers cannot rule out that horseplay at work can result in injury and there are cases where they can be held liable for the actions of their employees. To help prevent this, they need to have appropriate policies and procedures in place relating to horseplay that informs employees of the consequences of inappropriate behaviour at work and set out clearly what is considered acceptable and unacceptable behaviour.

Tips to prevent horse play.

Employees should:

• not engage or participate in any type of unsafe behaviour or horseplay, initiate it, or get pressured into participating in it.

• follow all regulations and work rules to ensure the safety of individuals or other employees.

• ensure protective equipment is used properly and operating machinery is in good repair and does not present a hazard.

• report those behaving in an unprofessional or unsafe way to a supervisor or manager.

Managers should:

• provide a safe and healthy work environment for all employees.

• take all precautions necessary to protect the safety and health of employees.

• outline policies against workplace horseplay in your employee manual

• educate and train employees on workplace safety.

• be an example of professionalism and not engage in any inappropriate behaviour or horseplay.

Contact us if you require further information.

Scaffolding

Many people are now feeling the full force that comes from a second national lockdown! The COVID-19 outbreak has ripped through many industries and caused major financial and medical unrest across the entire country. Even though people who work in construction are still able to operate during these new measures, it’s so important to think about how health and safety needs to be elevated substantially to safeguard both customers and staff. In the world of scaffolding, the individuals involved work outside and have the capacity to keep well away from other people. This still doesn’t detract from simple factors that need to be considered for safe and practical working. So, here are some things to think about if you are working in scaffolding during the new lockdown.

Almost every single day, people are going to be handling equipment and certain parts of scaffolding in order to gain access to various parts of a building. A simple deterrent against spreading anything through touching would be to wear protective gloves, but sanitising should also be brought into play on a regular basis. A deep clean should be conducted at the start of every day and the end. If you think certain things have been handled too much, then clean them down until you are satisfied they have been cleansed enough for future use.

If you think certain tasks can be handled by less people than you would usually call upon, then definitely look into this. A reduction of people you have milling around a building means you are less likely to see the virus spreading. Any projects that do require input from a lot of people could maybe look into staggering the shifts. This means the same manpower is utilised each day without having too many scaffolders operating at the same time.

People working in scaffolding will know that inspections are already a major factor behind any work. Should you require further assistance, you can call the necessary Building Control in order to establish best practices across your site. You also need to be careful if you have small-scale scaffolding for things like warehouses and workshops. A platform scaffold is going to be used on a frequent basis as people try to reach things above the ground. This could end up becoming a hotbed for the virus so perhaps only designate a handful of people to any ladders or platforms.

At the moment, the construction industry is able to carry on, but we all know this could change very quickly. There may come a point where certain areas across the country are deemed unsafe even for outside work as the virus continues to spread. You also need to ensure any staff working are clued up with the rules as even just one minor slip up could cause a wave of major issues. Health and safety has never been so important! So, think methodically and always act in the best interests of people who may be operating during what are unprecedented times.

Contact us if you would like further information.

Guest post written by B3 Scaffolding.