PPE regulations to change from April 2022

The HSE has released new regulations around the use of personal protective equipment (PPE) at work.

The new guidance is set to amend the 1992 regulations and will include specific Covid-19 guidance for workplaces.

The new PPE regulations PPER 2022 will remain unchanged in some areas from the 1992 regulations, but will now extend to Limb (b) workers (contractors, agency workers etc) who did not previously come under the 1992 regulations.

What does this mean for you?

Covid has changed the way we work forever. Previous blog regarding PPE and COVID, click here. This guidance from the HSE to include Limb (b) workers, is an example of the types of strategies needed in order to safeguard anyone on your site.

If you are an employer, you will need to familiarise yourself with the new regulations before 6th April 2022.

The PPE 2022 regulations places a duty on employers to provide necessary and essential PPE for both permanent and casual workers/contractors. Essentially anyone working on your site needs to be provided with the correct PPE for the job.

Risk assessments

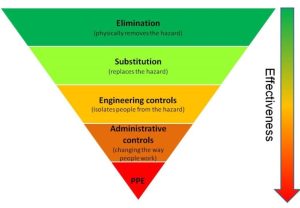

PPE risk assessments for all casual workers may place a small burden on employers. But the benefits of ensuring all site workers are properly equipped far outweigh the negatives. See it as a belts and braces approach to safety, which then covers all of your workforce and not just some.

We all have to play a part in ensuring that we minimise the spread of viruses that are potentially fatal. That means that prior to any new workers starting, each person must have a risk assessment and provided with the right PPE to safeguard their health and minimise accidents at work.

What PPE do I need?

PPE has changed a lot since the beginning of the pandemic. Workers are now demanding they are provided with the right equipment, which is now backed up by the new HSE regulations.

Depending on the nature of the work being performed, there are various types of ‘suitable’ PPE for workers. In some cases face masks are essential, but the level of protection afforded by each mask can be quite different. The best thing to do before buying any new PPE is to risk assess so that you buy the right face masks for the job. Last year we produced a blog post which discussed the various types of masks available and which one might be best for the job which might be beneficial when you are doing your research.

But of course PPE is never just face masks. To shop our collection of PPE including safety hats, goggles and more, click here to be taken straight to the PPE section of our shop.

Contact us for further information.

Guest Post William Dooley.